Typical milling cutters used at TTE.

End Mills Fig 1 Standard HSS End Mill

Fig 1 Standard HSS End Mill

End mills are tools which have cutting teeth at one end, as well as on the sides. The words end mill are generally used to refer to flat bottomed cutters, It can also described the cutting action – so end mills typically machine edges, faces and profiles. They do not have the capability to centre cut, so plunging into the material to create a pocket or slot is not possible with an end mill – you can see in fig 1 there is no cutting edge over the centre. This cutter is ideal for bringing to length your thread gauge, ending up the dice to make it a cube, the beam engine crank case. They are usually made from HSS “high speed steel” or cemented carbide, and have typically four flutes. Along with a slot drill they are the most common tool used in a vertical mill.

Slot Drills Fig 2 Standard HHS Slot Drill

Fig 2 Standard HHS Slot Drill

Slot drills are used for cutting a slot, as per the name, more clearance for the chips to come out of the back without clogging. You can see in fig 2 there is one flute that cuts over centre so it can be used to plunge cut a pocket or closed slot like a keyway. They are usually made from HSS “high speed steel” or cemented carbide, and have typically two flutes. Along with a slot drill they are the most common tool used in a vertical mill.

Fig 3

Fig 3 above clearly show the differences between the Slot drill & End mill

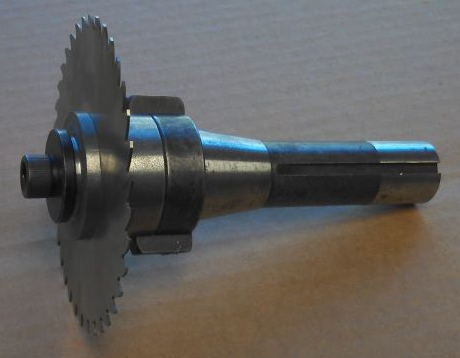

Fig 4 Slitting Saw

Fig 4 Shows a Slitting saw which is widely used to produce undercuts, slots, grooves and much more. During the manufacture of the “Beam Engine” there will be requirements to machine various slots.

Fig 5 Face Mill

Fig 5 Face Mill